Products

INFINITY Mesh Mist Eliminators

PRODUCT TYPES: Mesh Mist Eliminators

The most widely applicable type of mist eliminator is made of metal or plastic wire with a typical diameter of 0.006 to 0.011 inches, loosely knitted in a form resembling a cylindrical net.

This tube is flattened to form a two-layer strip typically 12 inches wide, which is then crimped in a diagonal pattern with ridges. When these strips are laid together, the ridges slant in alternate directions, forming an open structure through which gas flows freely. Such mesh can efficiently capture mist droplets as small as 5 microns (micrometers).

For eliminating droplets down to 1 micron in diameter, multi-filament yarns of various plastics or glass are knitted into the mesh. The result is called a composite or co-knit mesh.

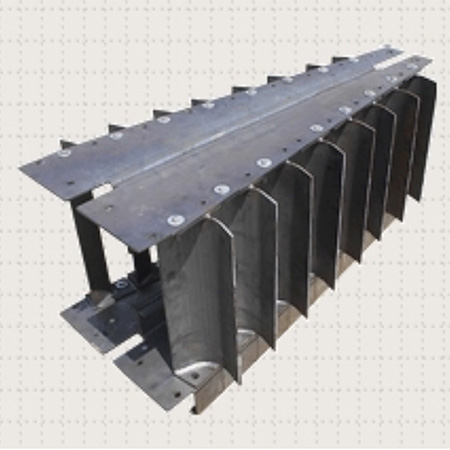

INFINITY Vane Mist Eliminators

PRODUCT TYPES: Vane Mist Eliminators

Also known as chevron or plate type, vane mist eliminators consist of closely spaced corrugated plates that force mist-laden gas to follow serpentine paths. These devices are generally not efficient for mist droplets smaller than about 20 microns, but they are sturdier than mesh pads and impose less pressure drop.

Vane arrays can be mounted horizontally or vertically. They are preferred in applications involving high vapor velocities, low available pressure drop, viscous or foaming liquids, lodging or caking of solids, slugs of liquid, or violent upsets.

Like mesh pads, vane units are usually round or rectangular. They are sometimes used in combination with mesh pads for optimum performance in special situations.

INFINITY Liquid-Liquid Coalescers

PRODUCT TYPES: Liquid-Liquid Coalescers

Our liquid-liquid separation technology can solve a wide range of separation problems involving immiscible liquids.

Whether it is capacity constraints, loss of valuable solvents or more stringent environmental compliance, we can help you meet these requirements. we offer different types of coalescer media and has solutions for even the most difficult to separate applications.

For new applications or for retrofits, we can provide cost-effective solutions for your liquid-liquid separation requirements.

INFINITY Inlet Diffusers

PRODUCT TYPES: Inlet Diffusers

Our inlet diffusers will correct flow imbalances and improve the operation of separators and distillation towers.

Higher gas flows into existing separators create poor gas distribution. Localized high velocities can also cause the gas to jet into the liquid surface. This in turn creates additional liquid entrainment and may flood the mist elimination device, resulting in liquid carryover. A properly designed inlet diffuser removes liquids and solids and evenly distributes the gas flow over the downstream separator.

In a similar manner, an inlet diffuser will improve operation of a distillation tower. Applications with flashing feeds or reboiler returns will see significant improvements.

Diffusers give improved phase distribution with negligible pressure drop.

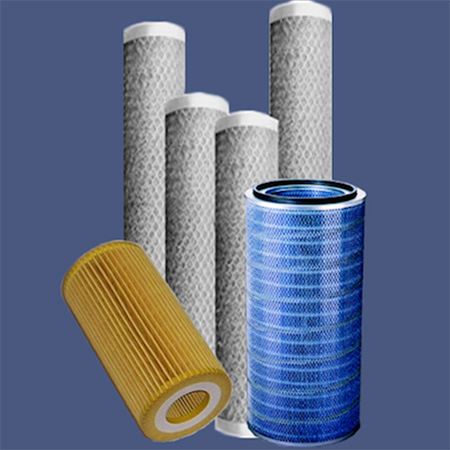

INFINITY Cartridge Filter

PRODUCT TYPES: Cartridge Filter

We offer all types of filters for various industrial applications, be it pleated filters, coalescing filters, fiberglass filters or absolute filters.

We offer replacement filters but our engineering staff, with use of the operating data of an application, can offer size and selection recommendations, and we also size and manufacture the vessel for the filters.

Our filters provide excellent filtration and coalescing characteristics and have structurally a superior strength.

The coalescing liquid-vapor filters are designed to remove aerosol (sub-micron) mist typically from natural gas applications.

REQUEST A PROPOSAL

INFINITY’S Team and partners have helped the industry Worldwide become more profitable and with minimal investment. We can provide you with a solution to do the same, contact us for an assessment and proposal.

COPYRIGHT 2022 ® ALL RIGHTS RESERVED. WEBSITE DESIGNED BY BRAINSTORM INTERNATIONAL, LLC